Machining a Scat Engine Plate

We’ve had a busy week in the shop, not with the Rock Bug but with shipping orders. We have managed to sneak in a little time here and there though, continuing the layout work necessary for the Scat engine plate. Finally, we had an opportunity to wrap this one up today, so we took to it.

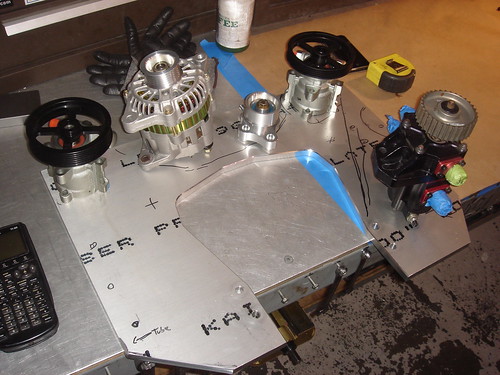

Starting from last Sunday, we continued with the engine plate layout and came up with the following configuration. The beauty of an engine plate is having the flexibility to put engine accessories where they fit best.

To conserve on space, we’re running a compact Suzuki Sidekick alternator. The OEM pulley did not match up with the rest of the Scat’s accessories, so we machined a custom 6 groove aluminum version to fit. In addition, a quick trip to the local Car Quest did not turn up anything exciting for a belt tensioner. So, we made that too.

After triple checking everything possible, we fixtured the engine plate and started machining.

When everything was said and done, we ended up with a pretty cool engine plate that weighed 5 lbs less then when we started. Not a bad way to wrap up the day. The next few days will focus on mounting the accessories to the engine plate, which will require a custom bracket here and there, as well as securing the engine plate to the chassis. Thanks for checking in and we’ll see you next time.