Crandon event schedule released; Ultra4s get ready.

Looks like the the Traxxas TORC schedule is out for Rounds 5 & 6, and would you look at that. Ultra4 racers will be running right after Pro 2s and right before Pro 4s.

| Friday, June 15th | |

|---|---|

| 8:00 AM | Spectator gate open to the public |

| 3:00 PM | PRO Practice PL, P2, P4, ULTRA 4 |

| 5:00 PM | PRO Qualifying |

| Round 5 – Saturday, June 16th | |

|---|---|

| 8:00 AM | Spectator gate open to the public |

| 10:30 AM | Coca-Cola Classix |

| 11:10 AM | Parsons Stock Truck |

| 11:50 AM | Cher-Make 1600 Light Buggy |

| 12:35 AM | Country Hearth Super Truck, Formula 4X4, & Sport 4 |

| 1:15 PM | Mole Lake.Com 1600 Buggy |

| 1:55 PM | Orv’s Super Stock Truck |

| 2:35 PM | Miller Lite Super Buggy |

| 3:15 PM | Traxxas PRO Light Truck |

| 4:00 PM | AMSOIL PRO 2WD Truck |

| 4:45 PM | ULTRA 4 |

| 5:30 PM | RAM PRO 4X4 Truck |

| Round 6 – Sunday, June 17th | |

|---|---|

| 8:00 AM | Spectator gate open to the public |

| 10:30 AM | Coca-Cola Classix |

| 11:10 AM | Parsons Stock Truck |

| 11:50 AM | Cher-Make 1600 Light Buggy |

| 12:30 PM | RAM PRO 4X4 Truck |

| 1:10 PM | AMSOIL PRO 2WD Truck |

| 1:50 PM | Country Hearth Super Truck, Formula 4X4, & Sport 4 |

| 2:30 PM | Mole Lake.Com 1600 Buggy |

| 3:10 PM | Orv’s Super Stock Truck |

| 3:50 PM | Miller Lite Super Bugyy |

| 4:30 PM | Traxxas PRO Light Truck |

| 5:10 PM | ULTRA 4 |

| 5:50 PM | 19th Annual Forest Country Potawatomi Chairman’s Cup Challenge |

Translation: all eyes are on Ultra4. In an effort in keeping the course as safe as possible, Dave has limited the number of Ultra4 vehicles to 15. So far, here’s the list of registered drivers:

1 JT Taylor

2 Cottin Rodd

3 Kevin Yoder

4 Thomas Grady

5 Jason Scherer

6 Erik Miller

7 Scott Decker

8 Roger Lovell

9 Bill Baird

10 Loren Healy

11 Kevin Sacalas

12 Mike Colville

13 Gary Ferravanti

14 Will Carter

15 Nick Nelson

We’ll be making the trip out to Crandon, posting updates when possible. Till next then.

Sources: Traxxas TORC & Pirate4x4.

4Word with Spidertrax Wheel Spacers.

We have the great honor and privilege of being part of Phil Howell’s most recent 4Word in the July issue of 4Wheel Drive Magazine. In it, Phil republishes an online article we wrote back in September of 2010 discussing the differences between our in-house manufactured wheel spacers and an unamed brand import spacer.

Before we repost our original blog article below for your reading enjoyment, there’s one quick disclaimer we’d like to make. The artcile as it stands is 100% accurate, so nothing changes there. Looking back however, we’d wish for possibly a better title than “Domestic vs. Import”. In the end, this is a poor choice of words as quality products can be made, well, anywhere. The article wasn’t intended to sell the idea that quality products can’t be made outside the US, rather it attempts to focus on the well documented issues of outsourcing (domestic or import) vs in-house production.

As this article demonstrates, the disconnect between retailer and manufacturer is increasing to the point where retailers have honestly no clue what they are actually selling. Sure, on paper they are told by the outsourced manufacturer “Yes, this product is certified 6061T6.” but in the end this means little to nothing, leaving only finger pointing as a end all solution. So, in our revised summary, we’ll say next time you purchase a product, any product for that matter, ask where and who it’s made by. If the retailer is unable, or unwilling, to answer that simple question be very cautious.

Domestic vs. Import Wheel Spacers: Mechanical & Material Analysis

Published on September 2nd, 2010. Original article can be found here.

1. Introduction

The seemingly unending debate of outsourcing & offshoring is back on top of America’s “What Matters Most” list. As the proud co-owner of Spidertrax Off-Road, an American company that designs & manufactures its products in-house, it should come of no surprise what side of this debate I sit. My interests however in publishing this article lie not in politics but in engineering ethics, focusing not on “you get what you pay for” but rather “you didn’t get what was advertised”.

Below is a detailed mechanical & material analysis between a Spidertrax JK Wheel Spacer (Domestic) & an “Unnamed Brand”* JK Wheel Spacer (Import). The take away here is not so much one product being superior to another. The issue is with the import wheel spacer being advertised as using 6061-T6, the same high quality material used in our domestic wheel spacer. Although these claims leave the impression that both products are virtually identical, the analysis detailed below tells another story.

*Before moving onto the results, I wanted to clear up any confusion ahead of time regarding the use of “Unnamed Brand”. The conflict in sharing this identity comes from singling out just one manufacture as we have duplicated these same test results from other import wheel spacer manufacturers. So, in an effort in “taking the high road” the import manufacture in this test will remain nameless and be referred to only as “Unnamed Brand”.

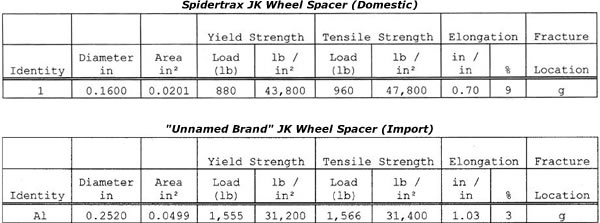

2a. Tensile Test (Aluminum Spacer)

Both domestic and import JK wheel spacers are advertised as using “6061-T6” aluminum. As referenced on MatWeb, Aluminum 6061-T6 should provide a minimum Tensile Strength (Yield) of 40,000 psi & a minimum Tensile Strength (Ultimate) of 45,000 psi.

As shown above, our domestic wheel spacer exceeds the minimum requirements for 6061-T6 (as advertised). The import wheel spacer, on the other hand, is off nearly 35% in terms of Tensile Strength for 6061-T6 (not as advertised). What is just as, if not more, concerning is the closeness in value between Yield Strength and Tensile Strength for the import spacer. This closeness in value suggests the material is cast and not billet (also not as advertised).

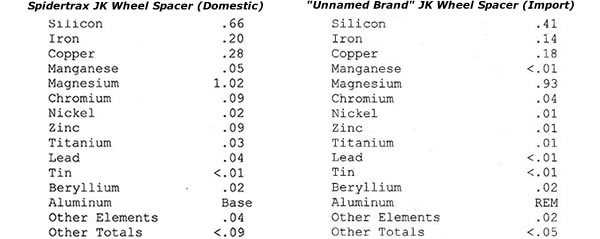

2b. Chemical Analysis (Aluminum Spacer)

This test confirms that, although there are differences in material composition as shown below, both our domestic wheel spacer & import wheel spacer conform to a 6061 series grade.

There is an important distinction made when combining the results of both the tensile test & chemical analysis though. When combined, the results clearly show our domestic wheel spacer is indeed billet 6061-T6 (as advertised) while the import wheel spacer is cast 6061 (not as advertised).

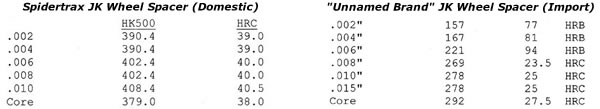

2c. Hardness (Wheel Stud)

The last test is a cross sectional hardness traverse on the wheel stud (a component which is pressed into the wheel spacer).

The results, as per SAE J429, indicate our domestic wheel stud exceeds Grade 8 specification (as advertised) while the import wheel stud meets Grade 5 specification (not as advertised).

3. Conclusion

As shown in the above analysis our domestic wheel spacers are manufactured from billet 6061-T6 aluminum and run Grade 8 wheel studs as advertised. Although the import wheel spacer is advertised using these same high quality materials, the above analysis proves it is manufactured out of nothing more then cast 6061 running Grade 5 wheel studs. “Buyer Beware” certainly doesn’t capture these outrageous findings.

For reference, you can also download a copy of the complete Domestic & Import metallurgical reports. All testing as detailed in this article was performed by Colorado Metallurgical Services (CMS). Spidertrax Inc. (Spidertrax Off-Road) is not affiliated with or a subsidiary of CMS.

A little more prototype action; IFS bulk heads.

The prototyping continues, as we CNC machine a few extra IFS bulk heads this morning. CNC machining these bulk heads, instead of using just a flat plate, is the secret behind how we’re able to package a shaft bearing over 20% larger than the competition. All right, then, back to work.

Miller Motorsports action reel.

Just a little Miller Motorsports action to get your Thursday going. Courtesy of HeavyMetalConcepts.