What it Takes to Win: Derek West’s Spider 9 Setup

“Spidertrax is the best to deal with. Not only do they have the best axle components available, they also offer the best customer service by giving exact lead times and shipping info. I have been using Spidertrax components for almost a decade and can attest to the strength and quality their product offer.” -Derek West

It’s been an awesome year. To date Spider 9 Axles have taken 1st place at King of the Hammers, The Stampede, King of Italy, French Xtreme, Croatia Trophy, Badlands (won by Derek West, photo as featured above), and just very recently the Breslau Rally (congrats Jim Marsden, more to come on that in the future post). This is just for 2015, the racing season is still young!

It was Derek’s recent win at Badlands that got me thinking. He’s one badass driver in one badass Ultra4, no argument there given his current 1st place standing in US series points, but what makes his Ultra4 so unique, so special? Is Derek running custom parts that only he has access to? Of course this is far from the case, which was the inspiration for writing this article. EVERY SINGLE SPIDER 9 PART on Derek’s Ultra4 racer can be purchased online or on the phone, available to everyone and anyone who’s building an off-road racer. Let’s not stop there though, the story that follows will detail the EXACT Spider 9 setup (axle dimensions, parts, everything we could think of) that’s under Derek’s winning machine, so that you to can see what it takes to grab those top podium spots.

Let’s dive right in.

The Build Sheet

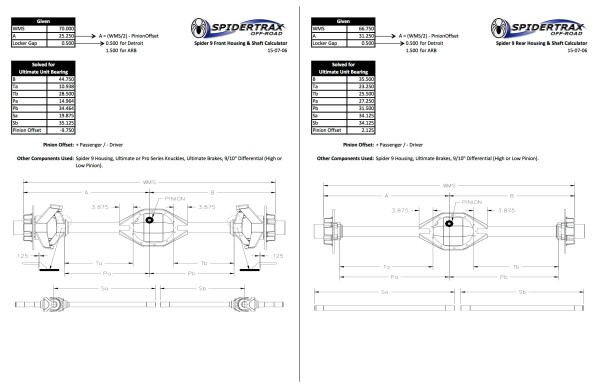

Spider 9s are designed with the builder in mind. Yes you can have your Spider 9 fully welded up and ready to go from one of our authorized Spider 9 resellers (more on that later), but you can also weld on your own housing ends. To make this process a little bit easier, we offer Spider 9 Builder Sheets. In an effort of keeping things simple, and making spreadsheets cool again, designing your own Spider 9 front and rear axle is as easy as entering in 3 pieces of information: your Wheel Mount Surface (WMS), distance from pinion to WMS (A), and the locker you’re running. That’s it. With these details you’ll have all the calculations you need to cut and weld up your own Spider 9. Oh, you will need Excel to use this builder sheet, couldn’t find a way around that one.

Spider 9s are designed with the builder in mind. Yes you can have your Spider 9 fully welded up and ready to go from one of our authorized Spider 9 resellers (more on that later), but you can also weld on your own housing ends. To make this process a little bit easier, we offer Spider 9 Builder Sheets. In an effort of keeping things simple, and making spreadsheets cool again, designing your own Spider 9 front and rear axle is as easy as entering in 3 pieces of information: your Wheel Mount Surface (WMS), distance from pinion to WMS (A), and the locker you’re running. That’s it. With these details you’ll have all the calculations you need to cut and weld up your own Spider 9. Oh, you will need Excel to use this builder sheet, couldn’t find a way around that one.

The Builder Sheet snapshot above is Derek West’s exact Spider 9 setup, complete with WMS, pinion offset, and axle shaft lengths. Worth noting he is running spools front and rear, so when selecting your locker option remember ARB is just ARB, but Detroit is “Detroit, Gearworks, Yukon, or Spool”. Now for the parts.

The Parts List

Almost everything listed below is available to purchase online, as such we’ll link directly to their product pages. Some items are marked with an asterisk (or two), those are available for purchase but you’d have to call that order in.

Front Spider 9

- Spidertrax Spider 9 Pro Series Axle Housing (3-1/2″ OD x 1/4″ Wall)

- Spidertrax High Performance Double Sealed Oil Seal Kit (For 1/4″ Tube)

- Spidertrax Pro Series 60 Knuckle Kit (3-1/2″ Housing Ends)

- Spidertrax Ultimate Unit Bearing (6 on 5-1/2″ x Pro Series Studs x 40 Spline x RH Spindle)*

- Spidertrax Ultimate Unit Bearing (6 on 5-1/2″ x Pro Series Studs x 40 Spline x LH Spindle)*

- Spidertrax Aluminum Brake Hat (5-1/2″ BC)

- Spidertrax 14″ Pro Series Rotor (For 5-1/2″ BC Hat)

- Spidertrax LSK Caliper Mount Kit (14″ Rotor)

- Wilwood Dynapro Bridged 6 Piston Caliper – .38″ Disc Width x RH

- Wilwood Dynapro Bridged 6 Piston Caliper – .38″ Disc Width x LH

- Wilwood Dynapro Type E Polymatrix Pad Set (Pair)

- Spidertrax Pro Series 300M 40 Spline Stub Shaft

- Spidertrax Ultimate 35 Spline 300M Inner Axle Shafts, 300M Yokes**

Rear Spider 9

- Spidertrax Spider 9 Pro Series Axle Housing (4” OD x 1/4″ Wall)

- Spidertrax Chromoly Full Floater End Cup Kit (4″ Tube)

- Spidertrax Ultimate Unit Bearing (6 on 5-1/2″ x Pro Series Studs x 40 Spline x RH Spindle)*

- Spidertrax Ultimate Unit Bearing (6 on 5-1/2″ x Pro Series Studs x 40 Spline x LH Spindle)*

- Spidertrax Aluminum Brake Hat (5-1/2″ BC)

- Spidertrax 14″ Pro Series Rotor (For 5-1/2″ BC Hat)

- Spidertrax UEC Caliper Mount Kit (14″ Rotor)

- Wilwood Dynapro Bridged 6 Piston Caliper – .38″ Disc Width x RH

- Wilwood Dynapro Bridged 6 Piston Caliper – .38″ Disc Width x LH

- Wilwood Dynapro Type E Polymatrix Pad Set (Pair)

- Ultimate 300M Floater Shafts 40 Spline

+ Derek’s other bits needed to complete his Spider 9, that we don’t directly sell, include Mega9 thirds w/ 5.40 gears, 35 spline front spool & 40 spline rear spool, Swepco 250 gear oil, & Yukon Super Joints.

* For racers who have switched from our older Pro Series Hub to the Ultimate Unit Bearing, we make a wheel stud that makes this transition easier on your wheels and wallet. The Ultimate Unit Bearings listed in Derek’s parts list above have wheel studs that mimic the older Pro Series Hub wheel studs. They are available for purchase over the phone, BUT WE DO NOT RECOMMEND THESE. They are available so as to make the transition easier, but the 5/8″ fully threaded studs as sold online are a much better setup. So swapping out Derek’s Ultimate Unit Bearing for this one in right hand and this one for left hand would be what we’d recommend on new builds.

** Thanks to the barely touches the throttle driving style of Erik Miller, we now manufacture 2 piece axle shaft yokes out of 300M. Complete with AMS heat treating specification (double tempering, snap tempering, cryogenic treatment), it’s as good as it gets. The Ultimate 300M Inner Shafts we sell online would be the same ones under just about every Spider 9 you see in competition, but these use a 4340 yoke along with 300M inner shaft. If you’re looking to spend more money, we do sell front axle shafts with both 300M inner shafts AND 300M yokes, which is what Derek has. You’d have to call that order in, but the model no. is AXLUD602M and at the time of this post, retail lists at $1,699.00 a pair.

The Assembly

As mentioned earlier, while we’ve designed Spider 9 axles with the builder in mind (you weld on your own ends), you can also work with an authorized Spider 9 reseller to have your Spider 9 welded up for you. In the case of Derek West, his entire Spider 9 was assembled by Jimmy’s 4×4. They took care of welding on the ends in addition to fabricating and welding on the suspension components, trussing, and steering brackets & arms. So, if you’re in the market of having this work done professionally, no problem. Give Randy at Jimmy’s 4×4 a call.