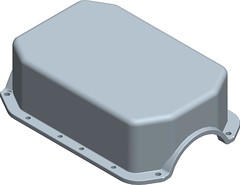

The Scat V4 continued getting our undivided attention this week. Starting from last Sunday, we finished up the last pieces of the engine plate accessories and quickly switched focus to the oil pan. We were faced with a choice of modifying the existing hacked up oil pan or making a custom oil pan completely from scratch. Modifying the oil pan is necessary because, due to the Rock Bug’s very tight clearances, we need to run the exhaust underneath it. Since we are running a dry sump, we do have the option of running a lower profile oil pan which would greatly help with the exhaust layout. Yes we know the clock is ticking, but this one seemed too fun to pass up. Therefore, first thing on Monday we started designing the Rock Bug’s Scat V4 custom billet oil pan.

For you Chevy fans out there, the shape of this oil pan may look somewhat familiar. A Scat V4 is built from the same platform of a Chevy 350. Without getting into too much detail here, the center 4 cylinders from the Chevy 350 design are removed, making the platform for this custom Scat V4 engine. So the oil pan has a similar shape from the 350 but the overall length is quite a bit shorter.

The Scat’s oil pan will be machined from a solid block of 6061T6 aluminum. This raw block of 6061T6 weighed in at 50.51 lbs. With a finished machined weight targeted under 5 lbs, there is no question here we will be making a lot of chips! Let the machining begin.

We had about 3 hours into machining and welding and are happy to say the end result was well worth it. On the first try, the Rock Bug’s Scat V4 engine is now the proud owner of a custom billet aluminum oil pan.

This weekend, we will continue work on the exhaust, staying right on target with having the Scat V4 ready to ship early next week to the engine builder. Until next time, thanks for checking in.

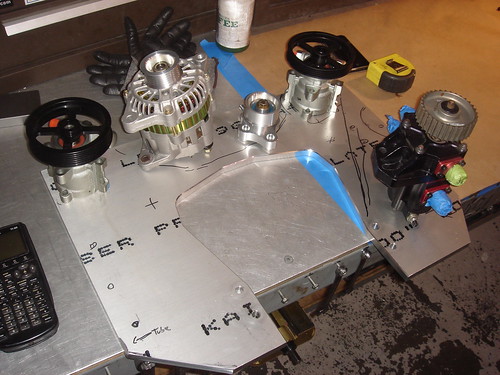

We’ve had a busy week in the shop, not with the Rock Bug but with shipping orders. We have managed to sneak in a little time here and there though, continuing the layout work necessary for the Scat engine plate. Finally, we had an opportunity to wrap this one up today, so we took to it.

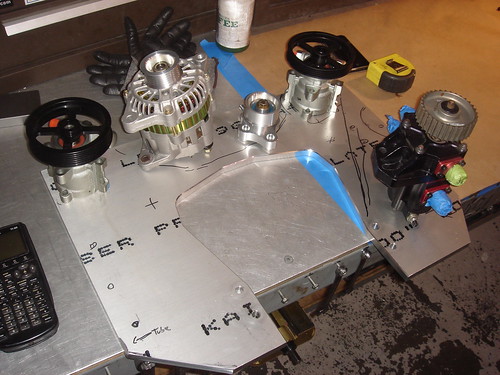

Starting from last Sunday, we continued with the engine plate layout and came up with the following configuration. The beauty of an engine plate is having the flexibility to put engine accessories where they fit best.

To conserve on space, we’re running a compact Suzuki Sidekick alternator. The OEM pulley did not match up with the rest of the Scat’s accessories, so we machined a custom 6 groove aluminum version to fit. In addition, a quick trip to the local Car Quest did not turn up anything exciting for a belt tensioner. So, we made that too.

After triple checking everything possible, we fixtured the engine plate and started machining.

When everything was said and done, we ended up with a pretty cool engine plate that weighed 5 lbs less then when we started. Not a bad way to wrap up the day. The next few days will focus on mounting the accessories to the engine plate, which will require a custom bracket here and there, as well as securing the engine plate to the chassis. Thanks for checking in and we’ll see you next time.

You figure with the holiday break we may get a few days off. Then again, with the King of the Hammers less then 3 months away, there is honestly no time to waste. So, Friday, Saturday, and Sunday we’re back hanging with the Rock Bug.

On Friday we managed to layout the location of all four shocks using the mockup shock we got last Monday from King. Rumor has it we should be seeing the actual quadruple bi-pass shocks from King in as soon as two weeks. The video above shows the mockup shock assembled on the driver side rear axle. All shock tabs still need to be capped and gusseted.

Friday, Saturday, and Sunday we focused on the front radiator mount. Check out the size of this Ron Davis 19” x 26” x 4” radiator in comparison to the small V4 Scat motor! Insane, especially at a weight close to 40 lbs including its dual 12” fans. This was the radiator designed for King of the Hammers though and we won’t be responsible for blowing up the Scat, so it stays :-). The front two support tubes are 1” OD x 0.095” 4130 chromoly while every other support tube is 1” OD x 0.065” 4130 chromoly. The two lower support straps are 1/16” thick 4130 chromoly plate. The front filler neck will be capped and moved.

We were also able to get started on machining the Scat engine plate on Sunday as all the Scat accessories are scheduled for delivery on Monday. The order here will be to first machine out the engine plate so we can bolt it on the front of the Scat as shown in the video here. With the exception of forgetting to turn off the coolant for the video, all went smooth. We will then mockup all the motor accessories, switching back and forth from the Scat to our CNC until everything is nice and happy. This work will continue tomorrow through the rest of the week. The Scat needs to be in the hands of the motor builder by the 15th of December, so focus will soon begin on exhaust, pulleys, dry sump, and anything else necessary in getting the Scat ready for running condition.

Just got word YouTube is now streaming videos in high definition. You need a fairly good connection to watch them, but the quality is unbelievable. Check out this video of the Rock Bug and compare it to the exact same one from the last blog post. Thanks YouTube!

[UPDATE: YouTube has since updated their video player. To watch in HD, first hit play, then hit the HD button located on the bottom right hand side of the video player.]