Big brakes have been a big deal in rock crawling and rock racing. We’ve been manufacturing 14″ diameter rotors since the early rock crawling days, and the extra stopping power at lower speeds has become an easy must-have. That being said, in today’s Ultra4 vehicles, especially those newer IFS powered versions, the large 14″ diameter rotor is a bit tight. Factor in mud and debris from those east cost races and clearance between the caliper and wheel can be an issue.

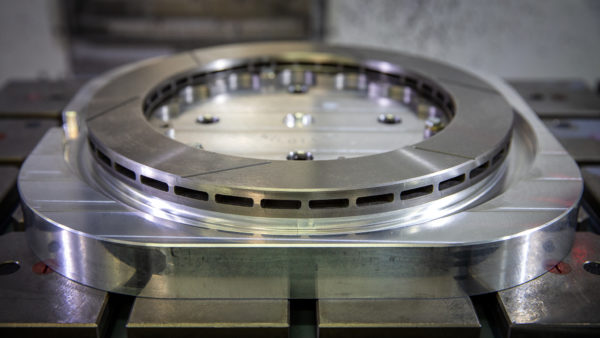

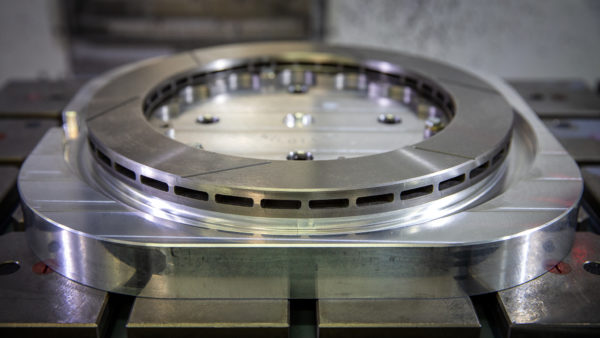

As such, the need for a slightly smaller rotor is born. Enter our prototype 13.5″ diameter rotor, which starts as Wilwood GT-36 Vented Rotor, precision machined down from 14″ to 13.5″. Brake hats, calipers, and pads all work as-is. The caliper pad also has full rotor contact, so no compromises either.

We’re giving these a test now, and so far so good; the extra caliper clearance for those that need it is obvious and welcome, and this rotor should do the trick. Stay tuned for more details.

We’re putting the finishing touches on the prototype weld-on high steer arms, and this latest set is our favorite yet. The design remains the same; laser cut normalized 4130 high steer brackets, tig welded, with forces properly transferred into the knuckle. The end result provides both a stronger arm and a stronger knuckle. For now, enjoy the latest photos and video above showing off what we imagine to be something closer to the finished product.

A “coming soon” modification to our Ultimate Unit Bearings that should make your pit crew happy. Here’s a sneak peak at a wheel stud speed start that will not only prove useful but should be cost effective once we dial in production.

With that, two other quick housekeeping items. First, best of luck to all Fallon 250 racers this weekend, make it a good one. Second, Labor Day is this Monday and we’ll be closed. Orders placed past 2pm on Friday will ship by Tuesday.

We have another fun prototype project we’ve been working on. Complimenting the Narrowed IFS Diff from last week, we put the finishing touches on our prototype Pro Series IFS Unit Bearing. Designed with Ultra4 IFS in mind, these all new unit bearings are 1″ more compact from WMS to CV flange per side over our current setup. In addition, combined Pro Series IFS Unit Bearing and axle shaft is 4lbs lighter per corner over our existing Ultimate Unit Bearing & axle shaft (that weight saving includes the addition of the drive snout as well). These prototype Pro Series IFS Unit Bearings were a blast to work on, we’re excited to see what will come of it. Until next time, make it a great weekend!

We had a lot of fun working on this new prototype narrowed IFS diff. Built for Ultra4, this diff is 1.4″ narrower than our current IFS housing, includes internal shell gussets for that extra bulk-head smashing drivers like to do these days, and in typical fashion face and bearing bores are all machined post welding. With that, back to work we go and make it a great weekend!